Smart factory

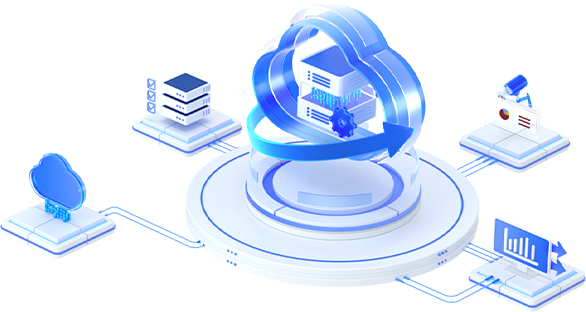

Based on the deep integration of IMS edge computing technology and industrial communication technology, the intelligent factory industrial IoT solution has built a complete equipment data collection and analysis system. By deploying Ames edge controllers in the factory workshop, the system can collect real-time operational data of various production equipment such as PLC, CNC machine tools, and industrial robots, including key indicators such as equipment status, process parameters, and energy consumption information. The controller has a powerful built-in edge computing capability, which can perform real-time pre-processing on the original data, including data cleaning, format conversion, time stamp alignment and other standardized processing. At the same time, it supports local computing tasks such as equipment status monitoring, energy efficiency analysis, and effectively reduces the cloud computing load.

The processed data is synchronously transmitted to workshop level visual dashboards and group level IoT cloud platforms through communication methods such as 4G/5G or industrial Ethernet. On IMS' own cloud platform or third-party cloud platform, the system further performs deep cleaning, storage, and intelligent analysis of data, using big data and AI algorithms to achieve advanced functions such as equipment health assessment, energy efficiency optimization, and production efficiency analysis. Ultimately, through intuitive visual reports, real-time data dashboards, and industrial process diagrams, comprehensive visual monitoring of equipment operation status, production progress, and quality indicators is provided to management personnel.