1、 Overview of the plan

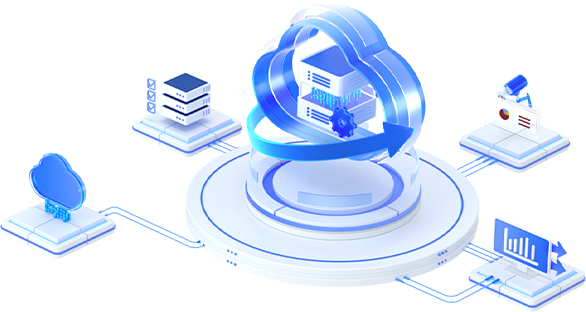

This plan is based on IMS Industrial Internet of Things technology and edge controllers, and constructs a complete factory equipment data acquisition, processing, and analysis system. By deploying Ames edge controller devices, data collection of various industrial equipment in the factory workshop is achieved. Data preprocessing and standardization are completed on the edge side, and the processed data is uploaded to the local kanban system in the workshop and the group level IoT cloud platform. The system ultimately provides factory managers with comprehensive visual monitoring of equipment real-time status and production processes through visual reports and industrial process diagrams, significantly improving the level of intelligent management in factories.

2、 System architecture

Data Collection Layer

Adopting IMS industrial grade edge controller, supporting multiple industrial communication protocols (Modbus, OPC UA, Profinet, etc.)

Connect PLC, CNC machine tools, industrial robots and other equipment through interfaces such as RS485/RS232, Ethernet, DI/DO, etc

Support the acquisition of various signal types such as analog, digital, and switch signals

Capable of collecting millisecond level data to ensure real-time production data

Edge computing layer

Implement data preprocessing locally on the controller, including:

Data cleaning (outlier removal, null filling)

Data standardization (unified units, timestamp alignment)

Data compression (reducing transmission bandwidth requirements)

All rights reserved by Shandong IMS IoT Co., Ltd. 鲁公网安备 37010502002005 Ministry of Industry and Information Technology filing number:鲁ICP备2023035307号-2